Rotating Drum Screen: An Essential Equipment for Efficient Waste Management

Introduction

Hello Music Enthusiast!

Welcome to our informative article on the topic of rotating drum screens. In today’s world, waste management has become a critical concern for industries and municipalities. As a drummer, you might not be directly involved in this field, but it’s always good to expand your knowledge. In this article, we will explore the concept of rotating drum screens, their applications, advantages, and disadvantages. So, let’s dive in and learn more about this crucial equipment for efficient waste management.

Image Source: ytimg.com

Before we proceed, let’s have a quick overview of what rotating drum screens are and how they work.

What Are Rotating Drum Screens?

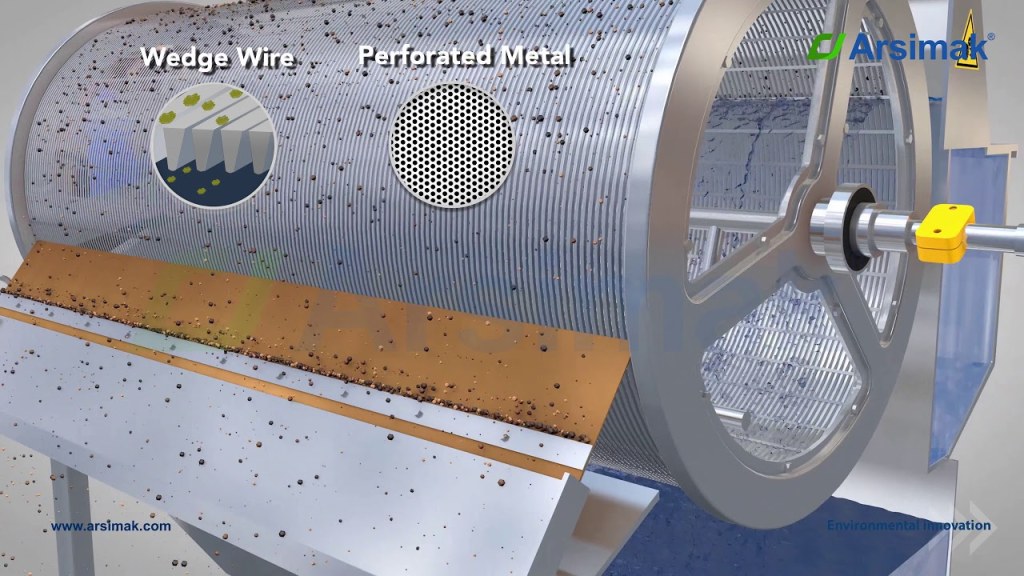

Rotating drum screens, also known as trommel screens, are mechanical screening machines used to separate solid waste from liquids and other materials. They consist of a cylindrical drum that is inclined or horizontally mounted and rotates at a predetermined speed. The waste material is fed into the drum, and as it rotates, the smaller particles pass through the screen, while the larger ones are retained inside the drum.

How Do Rotating Drum Screens Work?

The working principle of rotating drum screens is based on size separation. The drum is equipped with perforated or mesh screens with specific hole sizes. As the drum rotates, gravity and centrifugal force push the waste material forward. The smaller particles that fit through the screen openings are discharged through the lower end, while the larger particles continue to move along the drum’s length until they reach the discharge end.

Who Uses Rotating Drum Screens?

Rotating drum screens find applications in various industries and sectors that deal with solid waste management and material separation. Some of the common users include:

Municipalities: Municipal waste treatment plants use rotating drum screens to separate solid waste from wastewater streams.

Recycling Facilities: Recycling centers employ rotating drum screens to sort different recyclable materials based on their size and composition.

Composting Plants: Rotating drum screens are used in composting facilities to remove unwanted debris and contaminants from the composting process.

Construction Industry: Construction sites use rotating drum screens to separate construction debris from soil and other materials.

When Are Rotating Drum Screens Used?

Rotating drum screens are used in various stages of waste management processes. Some common scenarios where they are employed include:

Primary Treatment: In municipal wastewater treatment plants, rotating drum screens are used as the initial step in removing large solids from the incoming wastewater.

Pre-Sorting: Recycling facilities use rotating drum screens to pre-sort recyclable materials before further processing.

Landfill Operations: Landfill operators utilize rotating drum screens to separate solid waste from landfill leachate and generate cleaner leachate for treatment.

Industrial Processes: Industries involved in chemical production, mining, and manufacturing often use rotating drum screens to separate solid waste from process liquids or to recover valuable materials.

Why Are Rotating Drum Screens Essential?

Rotating drum screens offer several benefits that make them essential in waste management systems:

Efficient Solid Waste Separation: The rotating drum screens can effectively separate large and small particles, allowing for efficient waste segregation.

Reduced Maintenance: The self-cleaning mechanism of rotating drum screens minimizes clogging and reduces the need for manual cleaning, resulting in lower maintenance costs.

Space-Saving Design: Rotating drum screens have a compact design, making them suitable for installation in tight spaces.

Improved Water Quality: By removing solid waste from wastewater streams, rotating drum screens contribute to the overall improvement of water quality.

Increased Recycling Rates: The use of rotating drum screens in recycling facilities enhances the sorting efficiency, leading to higher recycling rates and reduced environmental impact.

What Are the Disadvantages of Rotating Drum Screens?

While rotating drum screens offer numerous advantages, it’s important to consider their limitations as well:

Screen Blockage: In some cases, the screen can become blocked or blinded due to the presence of sticky or fibrous materials, requiring manual intervention.

Complex Maintenance: Despite their self-cleaning mechanism, rotating drum screens may require periodic maintenance and replacement of worn-out parts.

High Initial Cost: The installation of rotating drum screens can involve significant upfront costs, especially for large-scale applications.

Limited Particle Size Range: Rotating drum screens are suitable for separating particles within a specific size range, and they may not be effective for extreme size variations.

Energy Consumption: The rotating drum screens require a continuous power supply for their operation, leading to energy consumption.

Frequently Asked Questions (FAQs)

Q: Can rotating drum screens handle a large volume of waste?

A: Yes, rotating drum screens are designed to handle high flow rates and large volumes of waste. However, the specific capacity depends on the screen size and the characteristics of the waste material.

Q: Are rotating drum screens suitable for wastewater treatment?

A: Yes, rotating drum screens are commonly used in wastewater treatment plants for the removal of large solids and debris from the incoming wastewater. They are an integral part of the primary treatment process.

Q: Do rotating drum screens require regular maintenance?

A: While rotating drum screens have a self-cleaning mechanism, they may require periodic maintenance to ensure optimal performance. This includes cleaning the screens, inspecting the drive system, and replacing any worn-out components.

Q: Can rotating drum screens be customized for specific applications?

A: Yes, rotating drum screens can be customized based on the specific requirements of different applications. This includes selecting the appropriate screen size, material, and drive system.

Q: Are there environmentally friendly alternatives to rotating drum screens?

A: Yes, there are alternative screening technologies available for waste management, such as vibrating screens and disc screens. These technologies offer different advantages and may be more suitable for certain applications.

Conclusion

Rotating drum screens play a vital role in the efficient management of solid waste and wastewater treatment processes. They offer efficient solid waste separation, reduce maintenance needs, and contribute to improved water quality and recycling rates. However, it’s important to consider their limitations, such as screen blockage and high initial costs. Overall, rotating drum screens are essential equipment for industries, municipalities, and recycling facilities striving for effective waste management and environmental sustainability.

Final Remarks

In conclusion, the use of rotating drum screens in waste management systems is crucial for achieving efficient solid waste separation and enhancing recycling efforts. While they may have certain limitations and require periodic maintenance, their benefits outweigh the drawbacks. It’s important for industries and municipalities to consider the specific requirements of their waste management processes and choose the appropriate screening technology accordingly. By investing in the right equipment, we can contribute to a cleaner and more sustainable future.