Title: Rotary Drum Screen: An Essential Equipment for Efficient Filtration

Introduction

Dear Music Enthusiast,

Welcome to our informative article about the rotary drum screen, an essential equipment for efficient filtration in various industries. In this article, we will explore the features, benefits, and applications of this innovative technology, as well as its advantages and disadvantages. Whether you are a drummer or simply interested in learning more about this equipment, we hope you find this article valuable.

Overview

Image Source: ytimg.com

Rotary drum screens are widely used in industries such as wastewater treatment, mining, food processing, and pulp and paper. They play a crucial role in the filtration process by removing solid particles from liquids or separating different sized particles. This equipment is known for its high efficiency, reliability, and low maintenance requirements. Let’s dive deeper into the world of rotary drum screens and discover their importance.

What is a Rotary Drum Screen?

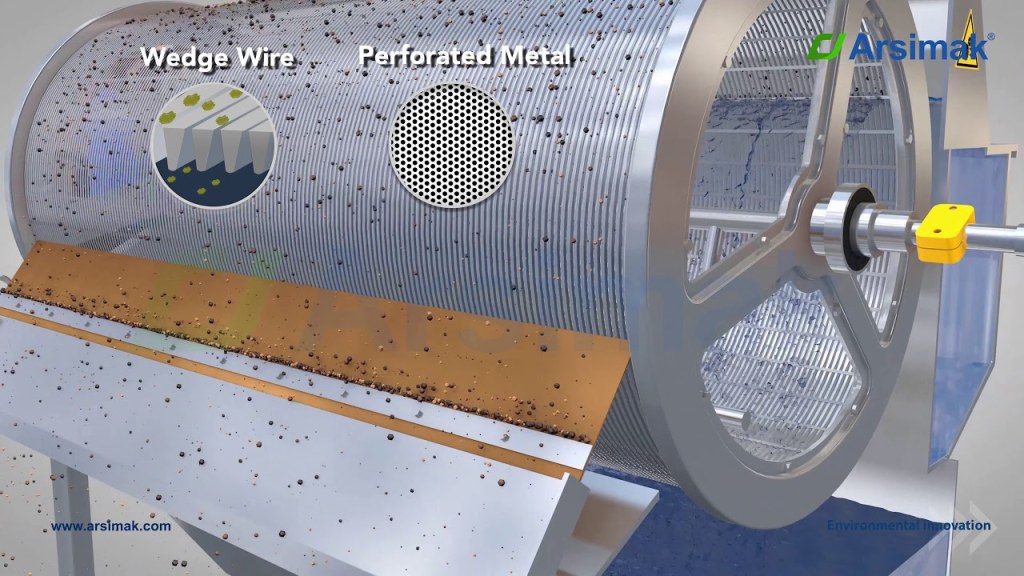

🔍 A rotary drum screen, also known as a trommel screen or rotary sieve, is a cylindrical-shaped device with perforated plates or wedgewire screens. It rotates on an axis and effectively separates solids from liquids or classifies particles according to their size. The rotation of the drum allows for efficient separation and screening of materials.

Who Uses Rotary Drum Screens?

Image Source: esmil.eu

🔍 Rotary drum screens are used by various industries, including:

1. Wastewater treatment plants: These screens remove debris, such as plastics, rags, and sticks, from wastewater before further treatment.

2. Mining industry: Rotary drum screens are used for grading and sorting minerals and ores.

3. Food processing industry: They are used for separating solid and liquid components in food products.

4. Pulp and paper industry: These screens help in the recovery of fiber and removal of contaminants from pulp.

5. Agricultural industry: They are used for composting and separating waste materials in agricultural processes.

6. Construction industry: Rotary drum screens are utilized for separating and recycling construction waste.

When is a Rotary Drum Screen Used?

🔍 Rotary drum screens are used in various stages of industrial processes, including:

1. Pretreatment: They remove large objects and debris from influent water or wastewater before further treatment.

2. Primary treatment: Rotary drum screens separate solid waste from liquids, improving the efficiency of subsequent treatment processes.

3. Secondary treatment: They help in the removal of fine particles and biological solids, ensuring higher water quality.

4. Tertiary treatment: Rotary drum screens are used for advanced filtration and polishing of treated effluent in wastewater treatment plants.

Where are Rotary Drum Screens Installed?

🔍 Rotary drum screens can be found in various locations, including:

1. Wastewater treatment plants: They are commonly installed at the inlet and outlet points of treatment systems.

2. Industrial facilities: Rotary drum screens are used in manufacturing plants, mines, and food processing facilities.

3. Agricultural operations: They can be found in composting facilities and agricultural processing plants.

Why Choose a Rotary Drum Screen?

🔍 Here are the key advantages and disadvantages of using a rotary drum screen:

Advantages:

1. High efficiency: Rotary drum screens offer efficient solid-liquid separation, ensuring cleaner water or processed materials.

2. Versatility: They can handle a wide range of materials and particle sizes, making them suitable for various industries.

3. Low maintenance: Rotary drum screens have a simple design and require minimal maintenance, reducing operational costs.

4. Cost-effective: Due to their durability and longevity, rotary drum screens provide long-term cost savings.

5. Compact design: These screens can be easily integrated into existing systems and require minimal space.

Disadvantages:

1. Initial cost: The initial investment for a rotary drum screen may be higher compared to other screening equipment.

2. Limited capacity: Depending on the size and design, rotary drum screens may have limitations in handling large volumes of materials.

3. Clogging: If not properly maintained, the screens can become clogged, affecting their efficiency and requiring cleaning.

How Does a Rotary Drum Screen Work?

🔍 Rotary drum screens operate on the principle of size separation. As the drum rotates, the material to be screened moves along the length of the drum and passes through the perforated plates or wedgewire screens. The particles smaller than the screen openings pass through, while the larger particles are retained and discharged at the end of the drum. The rotation of the drum ensures continuous screening and separation.

Frequently Asked Questions (FAQs)

1. What maintenance is required for a rotary drum screen?

🔍 Regular cleaning of the screens and routine inspections to check for any damages or blockages are essential for proper maintenance. Lubrication of moving parts and timely replacement of worn-out components are also recommended.

2. Can a rotary drum screen handle different types of materials?

🔍 Yes, rotary drum screens are designed to handle a wide range of materials, including wastewater, mining ores, food products, and more. The size and design of the screens can be customized to suit specific requirements.

3. How long do rotary drum screens last?

🔍 The lifespan of a rotary drum screen depends on various factors, such as the quality of materials used, maintenance practices, and operational conditions. With proper maintenance, these screens can last for many years.

4. Can rotary drum screens be retrofitted into existing systems?

🔍 Yes, rotary drum screens can be easily retrofitted into existing systems without major modifications. Their compact design allows for seamless integration.

5. Are rotary drum screens environmentally friendly?

🔍 Yes, rotary drum screens contribute to environmental sustainability by effectively removing solid waste and contaminants from liquids, thereby improving water quality and reducing pollution.

Conclusion

In conclusion, the rotary drum screen is an essential equipment for efficient filtration in various industries. Its high efficiency, versatility, and low maintenance requirements make it a valuable asset for wastewater treatment plants, mining operations, food processing facilities, and more. Despite the initial cost and potential limitations, the advantages outweigh the disadvantages, making the rotary drum screen a reliable choice for solid-liquid separation. Whether you are involved in these industries or simply curious about this technology, we hope this article has provided valuable insights. Take action today and explore the benefits of the rotary drum screen for your specific needs.

Final Remarks

Dear Drummer,

We have reached the end of our comprehensive article on rotary drum screens. We hope you found the information useful and informative. Before we part ways, it’s important to note that the content provided here is for informational purposes only and should not replace professional advice. If you require further assistance or have specific questions, we recommend consulting industry experts or manufacturers of rotary drum screens. Remember, informed decisions lead to efficient filtration processes and optimal results. Keep drumming and stay tuned for more informative articles!