C10 Drum Brake Diagram: A Comprehensive Guide to Understanding and Maintaining Your Brake System

Introduction

Dear Music Enthusiast,

Welcome to our informative guide on the C10 drum brake diagram. As a drummer, you know the importance of precision and rhythm, and the same applies to your vehicle’s braking system. Understanding how your drum brakes work and how to maintain them is crucial for your safety on the road. In this article, we will provide you with a detailed overview of the C10 drum brake diagram, explaining its components, functions, advantages, disadvantages, and more. So let’s dive in and explore the fascinating world of drum brakes!

Table: C10 Drum Brake Diagram

Image Source: wordpress.com

Component

Description

Brake Drum

The round, cylindrical part of the brake system that rotates with the wheel.

Brake Shoes

Curved metal plates lined with friction material that press against the brake drum to create friction.

Wheel Cylinder

A hydraulic device that pushes the brake shoes outward against the drum.

Brake Return Springs

Springs that pull the brake shoes away from the drum when the brakes are released.

Adjusting Mechanism

A mechanism that adjusts the position of the brake shoes as they wear down.

Anchor Pins

Steel pins that hold the brake shoes in place.

Backing Plate

A metal plate that provides a mounting surface for various brake components.

What is a C10 Drum Brake Diagram?

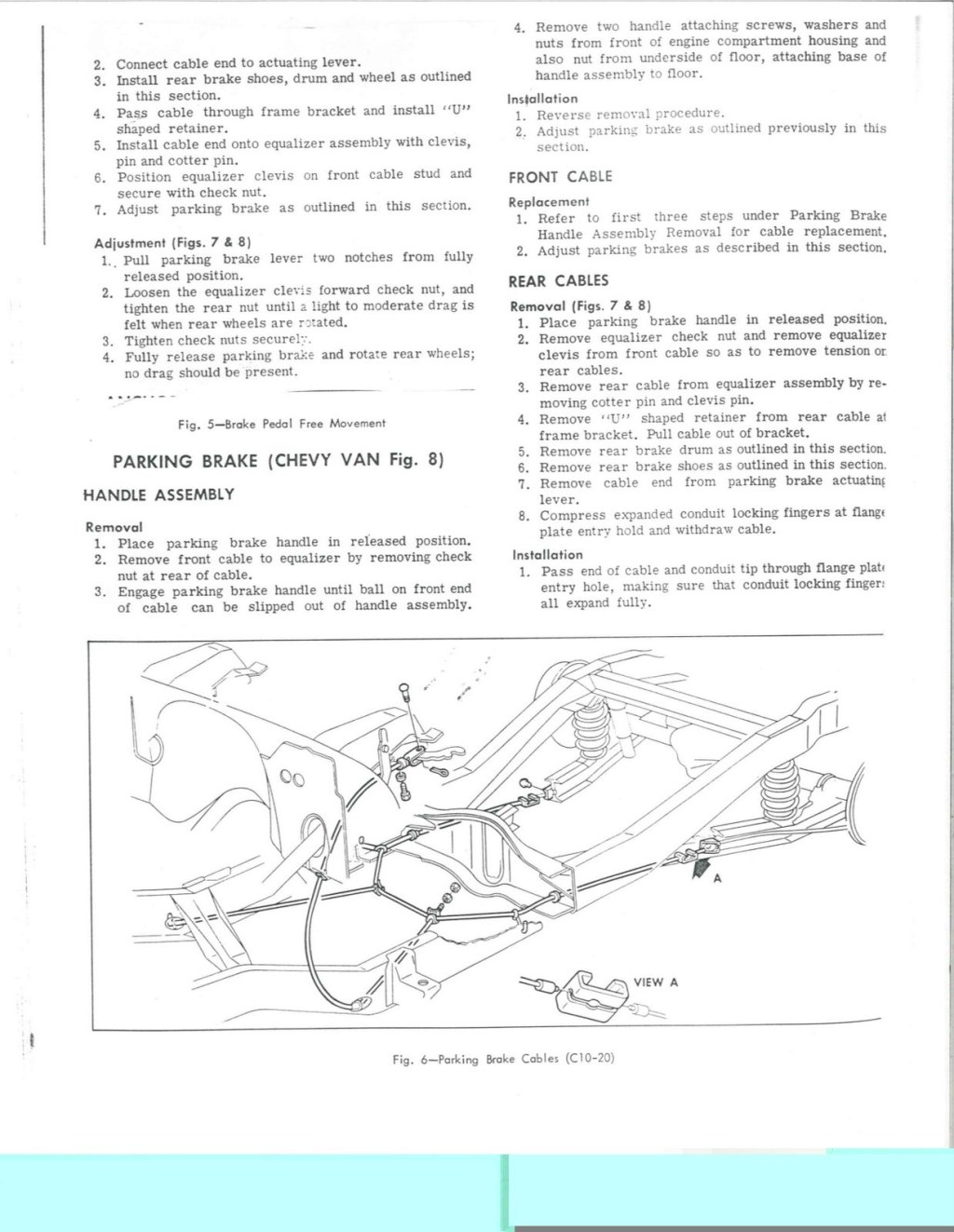

The C10 drum brake diagram is a graphical representation of the components and their arrangements in the drum brake system of a Chevrolet C10 truck. It illustrates how these components work together to slow down or stop the vehicle when the brakes are applied.

Who Uses C10 Drum Brake Diagrams?

Automotive enthusiasts, mechanics, and Chevrolet C10 truck owners often refer to C10 drum brake diagrams to understand the brake system’s layout and troubleshoot any issues. It serves as a valuable reference tool for anyone involved in the maintenance and repair of these classic trucks.

When Should You Refer to a C10 Drum Brake Diagram?

You should refer to a C10 drum brake diagram when inspecting, repairing, or replacing any components of your Chevrolet C10 truck’s drum brake system. Understanding the diagram will help you identify the specific parts, their locations, and how they interact with each other.

Where Can You Find a C10 Drum Brake Diagram?

A C10 drum brake diagram can be found in the truck’s service manual, online automotive forums, or websites specializing in Chevrolet C10 trucks and their components. These diagrams are also available in brake system repair guides or manuals.

Why is the C10 Drum Brake Diagram Important?

The C10 drum brake diagram is important because it provides a visual representation of the brake system’s intricate components and their connections. It helps users grasp the system’s functionality, aiding in proper maintenance, troubleshooting, and repair. Understanding the diagram ensures that the drum brakes perform optimally, ensuring safety on the road.

How Does the C10 Drum Brake Diagram Work?

The C10 drum brake diagram works by illustrating the sequence of events that occur when you apply the brakes in your Chevrolet C10 truck. When you press the brake pedal, hydraulic pressure is generated, pushing the wheel cylinder pistons outward. This, in turn, forces the brake shoes against the brake drum, creating friction and slowing down the rotation of the wheel.

Advantages and Disadvantages of C10 Drum Brake Diagram

Advantages:

Simple and reliable design

Cost-effective compared to disc brakes

Effective in low-speed applications

Disadvantages:

Prone to overheating and fade under heavy usage

Less effective than disc brakes in high-speed applications

Requires regular adjustment and maintenance

FAQs

1. Are drum brakes better than disc brakes?

While drum brakes have their advantages, disc brakes generally offer better stopping power and heat dissipation, making them more suitable for high-performance applications.

2. How often should I inspect my drum brakes?

It is recommended to inspect your drum brakes every 12,000 to 15,000 miles or as per the manufacturer’s guidelines.

3. Can I upgrade my C10 drum brakes to disc brakes?

Yes, it is possible to upgrade your C10 drum brakes to disc brakes. However, it involves replacing several components and can be a complex and costly process.

4. How can I adjust my C10 drum brakes?

You can adjust your C10 drum brakes by following the adjustment procedure outlined in your truck’s service manual. It typically involves turning the adjusting mechanism until the brake shoes are properly aligned with the brake drum.

5. Can I drive with worn-out drum brakes?

No, it is not recommended to drive with worn-out drum brakes as they can compromise your vehicle’s stopping power and pose a safety risk. It is essential to replace worn-out brake shoes and other components promptly.

Conclusion

In conclusion, understanding the C10 drum brake diagram is crucial for maintaining the braking system of your Chevrolet C10 truck. With a clear visual representation and knowledge of the components, their functions, and how they work together, you can ensure optimal performance and safety on the road. Regular inspection, adjustment, and timely replacement of worn-out components will ensure that your C10 drum brakes serve you reliably for years to come. So, take the time to familiarize yourself with the diagram and keep your brake system in top shape!

Final Remarks

Disclaimer: The information provided in this article is for educational purposes only and should not be considered as professional advice. Always consult the vehicle manufacturer’s guidelines and seek professional assistance when working on your brake system.